- 85c0fdfc 9fde 488f 8385 3db8c02917e6

- 075955b8 943a 4530 a183 b72dde90011e

- 7322483a e72d 45d1 9901 59cb8ac3f040

- de7351ed 6f3d 4ff3 b63b d9b12628c684

- 1ad0f1d0 8a48 46a4 b490 935e3d1fdf7d

- e45982f5 16b5 4544 97fa f8c3f26ae7b4

- 4658eeaf 55e5 4ccb 943c 1219b7f7dfd4

- 79290295 5e05 49e7 a1d2 b827ac283366

- 7c82c982 7b8c 4799 9732 e1217087a6b8

- 19bcaf2c 33ed 4066 9248 f967f2ff17ae

- 04bab249 5961 4032 848d c9bbd6e38464

- 19e0bffb c669 4cfe 98e7 b106b2aaa418

- daf2c6f4 a01d 44ba 85f4 d8331d1e6f01

- 6fa4fdac 5c46 4e5c bfa5 5c3370144090

- 7538b7fd 0d14 445e 8ce1 0c850cd717fe

- 054ee82d 72ed 403f b476 aacfed7099d4

- b8019379 ef4e 4e05 b7de a272af1e09a2

- e2e98ec8 e907 4f8c a8fd 050a613ad5ba

- 611955dd ee65 40fc 955f 78302176fe0f

Product Description

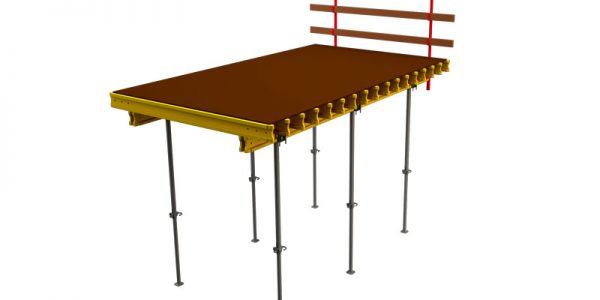

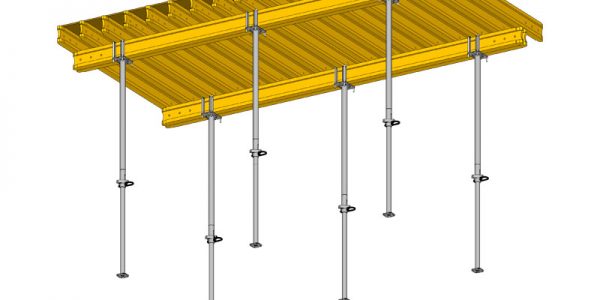

FORMO Table Systems designed and developed for slab formwork where we have a big number of pouring repetition such as high rise buildings as a good example where the system is reused on multiple stories of that specific building without being dismantled.

The assembled sections are either lifted per elevator or flown by crane from one story to the next by a special fork. The use of these systems can greatly reduce the time and manual labor involved in setting and striking of the formwork once assembled for one time only with different table sizes based on the configuration of slab shape to be supported. Plywood should be fixed on top of H20 beams by screws to ensure the stiffness of the top structure because of high repetitions plus installation of shutter release oil as well which will ensure easy smooth striking. Once the table are located on the next new floor as per provided shop drawings from FORMO, the customer has to fix filling plywood [ small pieces ] on top of H20 beams of these table forms to close gaps that will allow for striking process, all as per FORMO shop drawings as outlined earlier here.

Technical Details

Related products

Flex System

Flex system is a versatile slab formwork for ceilings in residential and industrial buildings adaptable to any slab type.

View Product DetailsFrame Form System

Table form adapts to any slab type and perfect for projects with high demands for finishing quality, safety and efficiency.

View Product DetailsBeam / Slab Side Support Brackets

FORMO beam system gives the contractors the ability to shutter the beams quickly up to the height of 1m.

View Product Details